Consistent humidity control is essential for successfully curing cannabis. In 1997, Boveda patented the technology that makes 2-way humidity control possible for moisture-sensitive products. As the global leader in 2-way humidity control, Boveda was asked to contribute a chapter on curing in the book, Medical Cannabis—From Marijuana to Synthetic Cannabinoids. To contact the publishing house, click here.

Quality cannabis is the best cannabis—but what traits make up a truly superior bud of cannabis flower?

While emphasis has previously been placed on strain genetics, the truth is that the genetic lines between strains are still unclear, and they are blurring more every day with advances in breeding and cultivation technology.

Regardless of strain, the current main focus for most cannabis growers is the cure. The curing process prepares the flower for the final stage of its life—human consumption. It allows the buds to fully develop their unique chemical profiles, leading to higher potency of therapeutic cannabinoids and terpenes.

In the words of Kenneth Morrow, a famous award-winning grower, breeder and writer:

“Drying and curing cannabis properly is an art in itself. Similarly, a tobacco farmer who grows tobacco for the finest hand-rolled cigars gives the highest level of care and attention to detail when drying and curing, which sets the stage for the final product.”

Curing cannabis can differ from one cultivator to another. Some in the industry use metal containers, while other producers use plastic or even glass containers. Desired moisture levels and curing times also vary. The common thread is that the environment must be dark and carefully controlled as much as possible to produce quality, consistent product.

WHAT DOES CURING DO?

The drying and curing process locks in active phytochemicals, causing the cannabis buds to become more fragrant and potent. Given the correct timing and environmental conditions, the result is similar to the ripening of fruit.

Well-cured buds provide the most flavorful smoke and increased psychoactive and body effects. On a chemical level, curing plays a significant role in transforming raw plant material into a finished product, as opposed to just drying and packing the “raw” flower.

Curing:

- Breaks down chlorophyll to dramatically improve the taste and smoothness of buds;

- Reduces harshness when cannabis is consumed;

- Eliminates the unpleasant “fresh hay” or “cut grass” smell, which is common with a new harvest;

- Consumers are less likely to cough or experience a headache after consuming properly cured cannabis flowers, which are also less likely to cause anxiety, racing thoughts, or paranoia because the chemical processes deep within the bud have been completed; and

- Curing at an optimal moisture level reduces the chance for mold or bacteria to grow on buds, keeping it safe for consumption.

HOW TO CURE CANNABIS

1. Harvest:

Cutting and drying cannabis plants should only be done when the buds are ripe and ready for harvesting. Prior to harvest, flush any remaining nutrients from the growing medium. For a week or more, run only clean water through the soil or block. This flushing forces the plant to use all of the remaining nutrients to fully develop its flowers. Once the plants are cut down, the time in which to correctly process these valuable flowers will be limited.

Some cultivators choose to cut the plants down at the base of the stem and hang the entire plant upside down. While the plant dries, gravity draws the remaining nutrients down into the buds. Others will cut off branches to hang. Still others prefer to cut and dry individual buds on a mesh screen, rack, or other flat, breathable surface.

2. Trim:

The amount of “extra” leaves to trim off of each individual bud is a personal preference. Although heavy trimming of flowers has been popularized in legal markets to increase visual appeal, much of the material trimmed off is actually quite rich and suitable to consume.

The first leaves to be removed are the “fan leaves”—the large iconic cannabis leaves. Fan leaves are not ideal for smoking because they have a relatively low cannabinoid content. For decades, cultivators have trimmed away fan leaves. They can, however, be used to make edibles or other infusions, juiced for their nutritive properties, or even composted (where allowed).

Beyond the fan leaves there are smaller leaves, called “sugar leaves,” which grow closer to the bud itself. They are covered in trichomes and generally high in THC and terpene content, just like the actual bud. Some growers choose to leave these tiny leaves intact to avoid losing any potency while drying. Sugar leaves, however, can cause a harsh smoke. They can also detract from the finished appearance of the bud when it is displayed in-store.

If your area is humid, it is advantageous to cut off as much leaf material as possible before curing. This helps speed up the drying process and prevents mold. If it is very humid where you live, you might consider actually removing buds from their branches for drying. Conversely, if you are in a very dry climate, leaving more leaves attached can help slow down the drying process and retain the integrity of the bud.

Dry:

The optimal drying environment is a contained area that is cool and dry with a constant temperature of 68º Fahrenheit / 20° Celsius and a relative humidity level around 50%. The goal is to dry your cannabis as close as possible to the humidity level at which you wish to cure or store the flower during the final steps of the aging process.

3. Burping:

After the drying process, cannabis buds are put into airtight containers. The flower still requires a low level of air circulation to regulate humidity and oxygen within the container. Therefore, the containers must be “burped” by periodically opening and closing the lids. Burping lets gas out and fresh oxygen in. Cultivators burp their buds repeatedly—from every 14 to 60 days.

Burping fine-tunes humidity levels and prevents accidentally over-drying the flower. When a 2-way humidity control product is used, burping for humidity control is no longer necessary, because these products automatically achieve and maintain optimal moisture levels inside flower containers.

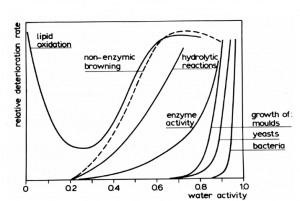

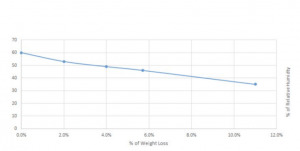

Reaction rates in food as function of water activity (Rockland and Stewart 1981)

4. Aging:

After all these steps are completed, the cannabis flower can continue to age in an airtight container for several more days or even weeks. This allows the internal chemical processes to continue maturing the flower. In some parts of the world, growers cure flower for several months. The aging process results in the developed product preferred for consumption.

Cultivators cure their harvest in everything from glass and stainless steel containers to turkey bags, totes, and buckets. Airtight containers are always best for curing and storing buds. The container you choose is not as important as what happens inside the container.

Throughout the later stages of the curing process, it is also important to watch for color changes. For example, some buds reveal an amber tint as they mature.

Although it might appear that buds require little attention once they are contained, this is not true. There is still a need to develop a good eye for ripe, cured cannabis.

5. Storing:

It is recommended that cannabis flower be stored without exposure to sunlight in a cool place. ASTM International furthermore suggests that all cannabis flowers be stored at a water activity (aW) level of between 0.55 and 0.65. This can be achieved by keeping flower in an airtight container that has a relative humidity (RH) of 55% to 65%. Maintaining this requisite aW throughout the supply chain—from completion of drying through merchandising, ensures safety and quality for the consumer.

Keeping cannabis between a 55% and 65% RH level also optimizes the potency, efficacy, flavor, aroma, and taste of the flower. Science has shown that when cannabis is stored within these proper humidity levels, flower can achieve up to 15% more terpene retention.

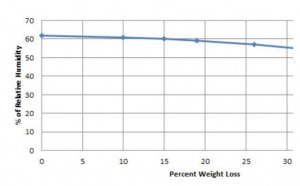

Using a saltwater sachet is the best way to conform to the ASTM water activity standard. Saltwater is the most reliable and stable means of maintaining a given relative humidity level due to the gradual liquefaction of natural salts. Comparable technologies such as glycerin-based solutions, hydrostatic polymers, and sponges are not able to maintain a predefined humidity level.

Salt solution maintaining 62% RH level over evaporation loss (Boveda 2016)

Glycerin solution’s incapability of maintaining 62% RH over evaporation (Boveda 2016)

BEST PRACTICES FOR CURING & STORING CANNABIS

Create an ideal environment for curing and storing, preferably in a place where you can easily control the light and temperature to ensure a cool, dark cure for your buds.

Use ideal equipment for drying, such as large glass jars, metal tubs, or buckets. Investing in proper gear will make the curing process easy and more reliable.

TO BE AVOIDED:

Do not dry or cure cannabis in containers that are not airtight, because it will be difficult to regulate the air and humidity.

Do not use orange peels, apples, lettuce, bread, or tortillas to manage the humidity or moisture level within your curing or aging containers. This is an old-fashioned method that can actually promote mold and bacteria within your container. Storing buds with decomposing food can also alter the flavor of your flower.

CONCLUSION:

Drying and curing cannabis flower might appear difficult at first and it surely involves some level of trial and error. But don’t overstress: While proper drying is absolutely vital to avoid mold, curing is more about personal preferences than hard science. Controlling airflow with a good container as well as humidity with a salt-based device takes two important variables out of the equation and allows to focus more on fine-tuning.

AUTHORS

Roni Stetter

Roni Stetter is a professional in the cannabis industry who has been touched personally by the plant. She has used it as part of a healthy pain management routine since 2010, and since that day she has worked hard to educate the world about the positive physical, mental, and societal effects of legalization.

Benjamin Patock

Benjamin is an author, speaker, and activist for consumer rights group. He works with Boveda, Inc., the global leader in 2-way humidity control. Benjamin is devoted to securing high quality standards for cannabis products around the world.

SOURCES

This chapter was written with the help of additional experts in the industry, including the cannabis professionals at GrowWeedEasy.

GRAPHICS

L.B. Rockland G.F. Stewart, Water Activity: Influences on Food Quality, Academic Press (1981)

Boveda Inc., Analysis of Salt Solutions as a Moisture Management System vs. Non-Salt Formulations (2016)