With wine production, for centuries it has been known that every environmental factor—from soil quality to harvest techniques to aging processes—affects the final product. That same level of quality assurance-minded scrutiny is now being applied to cannabis and hemp. With billions of dollars at stake and an increasingly discerning market of buyers and sellers, factors that come into play after harvest are more consequential than ever before.

When comparing two samples of cannabis flower, historically the attention has gone to the genetics and cultivation processes: sativa- or indica-dominant strains, indoor or outdoor growing environments. These discussions have long dominated the industry and media, as well as the conversations consumers have with their local budtenders.

But there’s an equally important factor that often gets overlooked: storage after harvest.

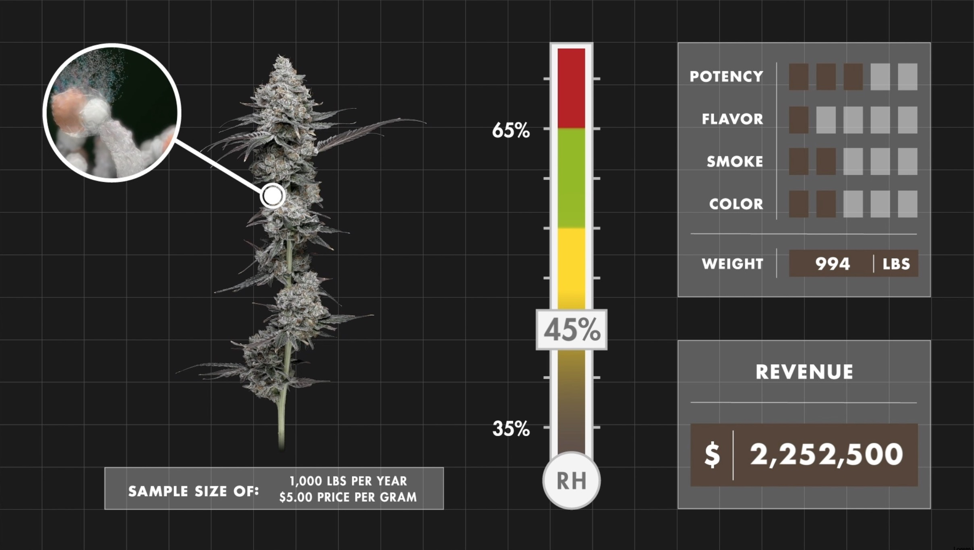

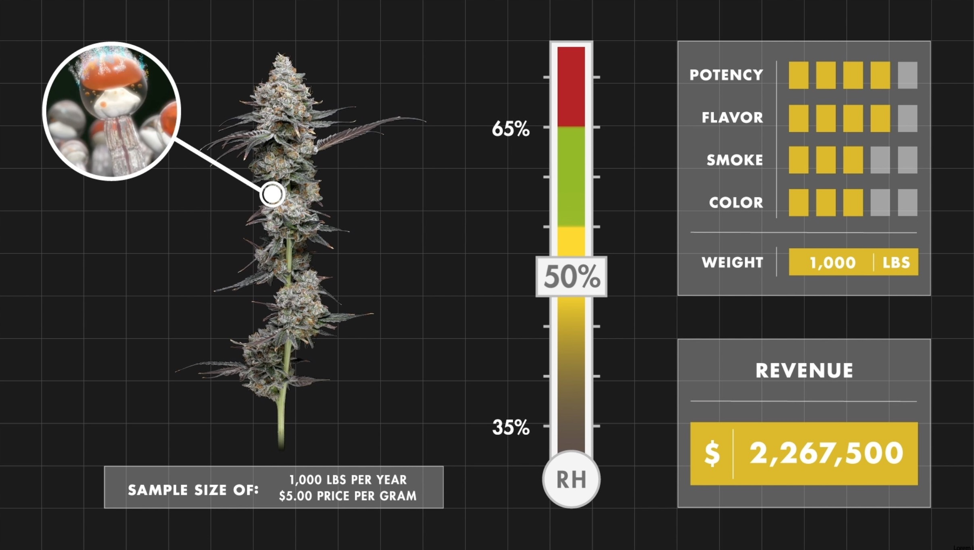

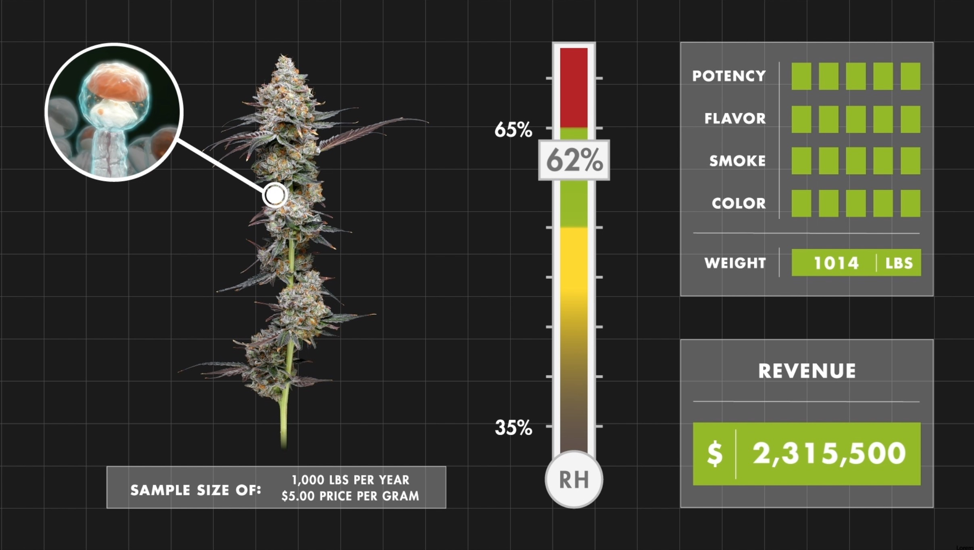

The relative humidity (RH) for storing

harvested-and-cured cannabis flower makes a critical difference in the quality,

safety, medical efficacy and value of the product. For cultivators and

retailers, investing in effective, dynamic moisture control can be

transformative for product quality—and can retain substantial weight (a.k.a. profit

margin), which is otherwise lost to evaporation and deterioration. Proper

storage of flower retains all the value, the cannabinoid profile and the

distinctive characteristics that develop via thoughtful growing and curing

practices.

Moisture Matters

Moisture fluctuations can have a substantial impact on the value and even the efficacy of cannabis flower. Too much moisture and the plant material becomes a breeding ground for mold and fungus. Too little and it dries out, causing significant losses in weight and key chemical components such as cannabinoids and terpenes. The same harvest can yield flower of vastly different quality, depending on whether or not it’s kept at an appropriate post-harvest moisture level.

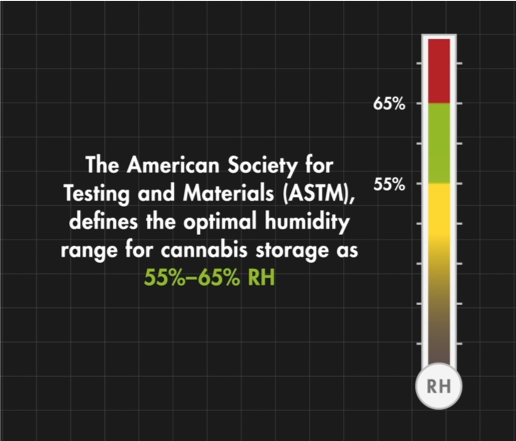

Storage for cured cannabis has an optimal RH range of 55-65%, according to ASTM International, a global organization that establishes industry standards for manufacturing and services.[1] Within the ASTM standards, additional research commissioned by Boveda—a humidity-control research and product development firm operating globally in food, tech and botanical sectors—has identified supplementary value gain by targeting a range of 58-62%.

The key variable for cannabis is RH, a measurement of water vapor compared to the saturation point of its current environment and temperature. For simplicity’s sake, this discussion will refer to optimal RH ranges for cannabis storage. Scientifically speaking, the environmental RH affects the flower’s free water level, known as water activity (Aw). Because water activity is expressed as a decimal, the values for RH percentage and water activity can be viewed similarly. For example: 0.58 Aw = 58%RH.

When cannabis stays in the optimal RH range, it realizes its full potential for quality and profitability. There are some stark consequences—from the medical to the economical—when there are deviations above or, more commonly, below this range.

Haphazard storage methods were forgiven in the early, unregulated days of the cannabis industry, but as standards and transparency increase across every stage of production and profit margins decrease, the market will deliver a painful rebuke in the form of lost revenue to cannabis companies that package and store their flower without humidity control in mind.

Research Findings: Lost Moisture is Lost Value

There are two central issues with overly dry cannabis: significant loss of weight and compromised cannabinoid profiles.

The weight of the flower directly correlates with profitability. The heavier the yield, the higher the market value. Simple enough, right? Not quite.

Cannabis flower needs to be dried and cured after cultivation, but some cultivators, processors and packagers only worry about keeping the flower below a particular humidity “ceiling” while neglecting to ensure the flower stays above a certain “floor.” It is not uncommon for cured cannabis to be stored for upwards of two months prior to sale or consumption, and by the time it reaches the end consumer, most cannabis sold in regulated environments in the U.S. and Canada is far too dry.

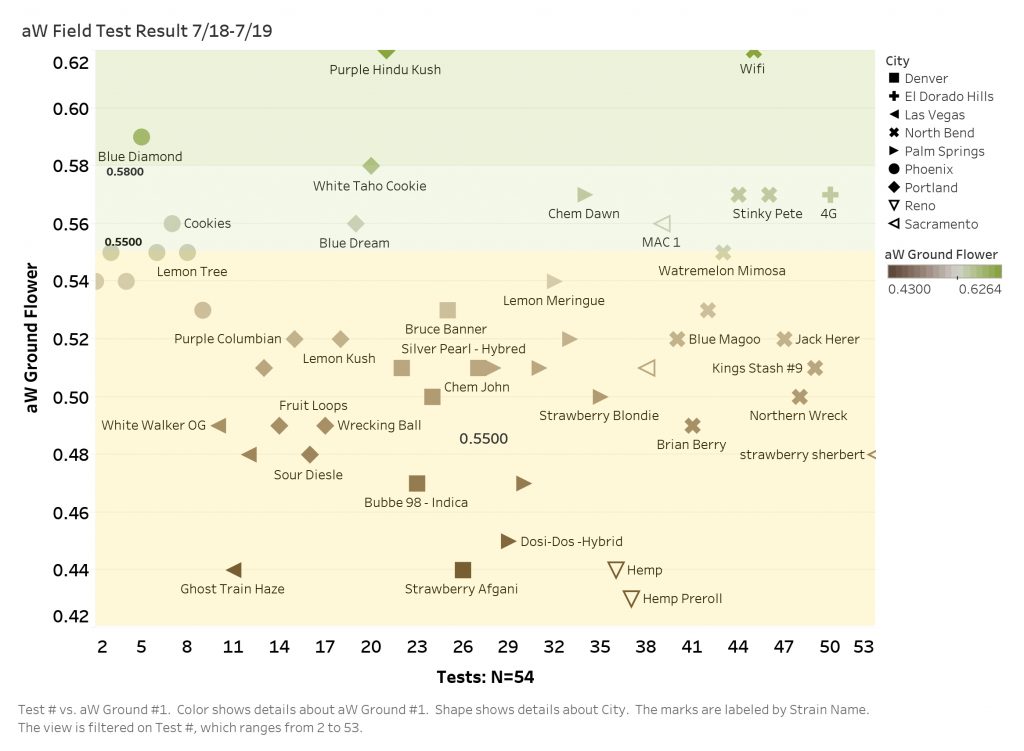

The results of a 2018 product analysis conducted by Boveda with third-party testing are eye-opening: Of 72 cannabis samples purchased across five state markets, 67% of samples were below the optimum RH range (55-65%). And of those flower samples that tested within the target RH range, multiple samples were teetering on the cusp of the lowest optimal RH threshold, indicating significant room for improvement across the board.

Overdrying directly affects the bottom line—much more than many cultivators realize. For example:

With 1,000 pounds of cannabis, if there’s a 5% reduction of RH below the optimal threshold, that equates to a loss of six pounds (2,721.6 grams); at $5 per gram wholesale, that works out to $13,607 in lost revenue. Regardless of current wholesale prices, this provides a sense of the scale of dollars lost, but not the limits. Boveda’s analysis found that a majority of the cannabis sold today is more than 5% below the optimal range—which comes with a corresponding loss in value. In fact, third-party testing reveals that a bulk of cannabis currently on the market is around 10% below the lowest acceptable moisture level.

Even within that optimal RH range where cannabis flower realizes its full potential, there are still tens of thousands of dollars to be gained from precisely maintained RH. Additionally, cannabis in the optimal humidity range maximizes all the qualities that attract and retain customers.

Why Some Producers Purposefully Go Too Dry

Cannabis is taxed according to its weight, and levels of cannabinoids such as tetrahydrocannabinol (THC), cannabidiol (CBD) and others are calculated as a percentage of flower weight.[2] Thus, many producers lower their tax burden and increase their reported potency by intentionally drying out their cannabis, then rehydrating it shortly before sale. The strategy might improve quarterly revenue, but it’s a long-term loser.

This method irrevocably damages the quality of the flower, encourages potentially problematic rehydrating methods, and invites excessive regulation.

The negative repercussions of such tactics are far more problematic for cannabis companies than any tax savings. Customer loyalty dries up even faster than unprotected cannabis flower with the realization the cultivator has an inferior product.

Beyond that, this ploy threatens the integrity of the entire cannabis industry. Manipulative practices like this serve as an open invitation for regulators to crack down and introduce stricter standards that would likely increase bureaucratic overhead and monitoring.

Protecting Trichomes from Damage and Degradation

Consumers, particularly medical patients, have a growing vocabulary to describe the cannabis components and characteristics they seek out, namely the various terpenes and cannabinoids that contain a majority of the plant’s medical efficacy.

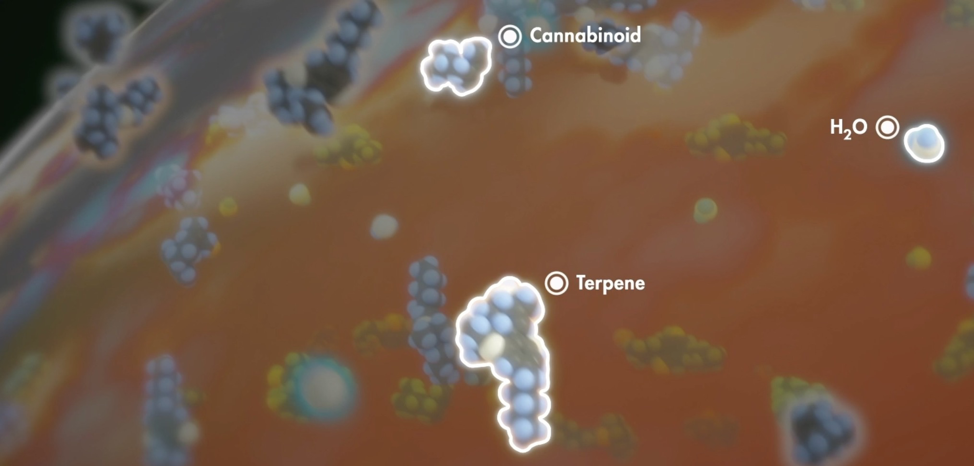

Cannabinoids are a diverse class of chemical compounds that engage the human endocannabinoid system, a vast network of receptors throughout the body. The percentages of THC, CBD and the overall chemical profile of cannabis flower often serve as shorthand for its potency, as well as an indication of what types of effects and health benefits the consumer may experience.

At least 104 cannabinoids have been identified in the cannabis plant.[3] So-called “rare cannabinoids” such as cannabigerol (CBG), cannabichromene (CBC), cannabinol (CBN), tetrahydrocannabivarin (THCV) and others have begun to receive further study as scientists examine how these compounds work on their own and in concert.

If cannabinoids describe the metaphorical horsepower of a cannabis strain, terpenes are the feel of the ride. Terpenes are also responsible for producing the aroma, taste and olfactory traits of the cannabis cultivar.

Terpenes are thought to shape the therapeutic and euphoric effects of cannabis. Some researchers have discovered that terpenes interact with cannabinoids, producing what’s known as an “entourage effect.”[4] This complex interplay of cannabis components may determine whether a strain is beneficial for people with anxiety, pain, spasticity or other neurological conditions, to name a few.[5]

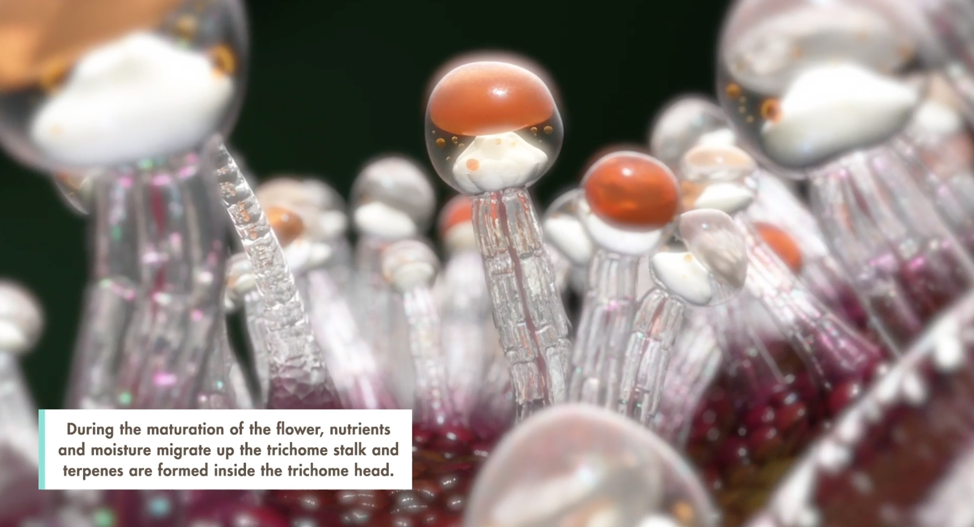

Terpenes and cannabinoids are housed within the plant trichomes—the delicate, resinous outer “hairs” of the flower. Since terpenes and cannabinoids are more or less what the consumers are paying for when they purchase cannabis flower, almost all of that flower’s market value is contained in this highly exposed and intensely fragile part of the plant.

As any veteran cultivator knows, overly dry cannabis spells big trouble for trichomes.

When harvested cannabis gets overdried, trichomes become brittle and fragile, breaking off and settling at the bottom of the package; they will not be recovered even if the flower is rehydrated. Because terpenes can volatize into the atmosphere when trichomes are compromised, if cannabis is dried out too quickly or for too long, terpenes will evaporate, negatively affecting the plant matter’s quality and flavor. The findings on evaporative terpene loss were documented in third-party lab tests commissioned by Boveda.[6]

Consumer Demands Are Evolving

Terpene and cannabinoid levels printed on packaging labels attest to the quality and effects a consumer could reasonably expect to experience. But it’s an open question as to whether the qualities present in the flower when it was tested and labeled are still there when the final product is consumed.

It is increasingly important for cannabis producers to get this right, both from a customer satisfaction and a regulatory compliance standpoint.

As legislative reforms continue to widen the reach of regulated cannabis markets across the country and internationally, seasoned consumers are becoming more sophisticated in their knowledge of the chemical composition of cannabis strains, and are increasingly seeking out highly specific strains with precise terpene and cannabinoid levels in mind.

Thanks to the ubiquity of social networks and the

immediacy of digital communications, the feedback loop from cultivator to

consumer is more public and apparent. That trend will undoubtedly follow the

rapid growth trajectory of the industry at large. Whereas in the past when any

cannabis flower would do, cultivators today are feeling the quality demands of

the market more acutely.

Mold: A Rarer Problem with Bigger Consequences

When storing cannabis flower, many consumers—and some cultivators and processors—seek to combat overdrying with rudimentary tools such as fruit rinds, wet paper towels, tortillas and the like. These methods of rehydration are not just imprecise, they create potential health hazards. While harvested cannabis typically does not develop Botrytis cinerea or “bud rot,” it can become host to Aspergillus, a dangerous mold that thrives in high-moisture areas.

For the cultivator, mold growth means immediate lost revenue, and may threaten the long-term viability of their brand.

Mold-ridden cannabis is valueless in the marketplace and must be destroyed, particularly since pathogens such as Aspergillus can be extremely dangerous for the health of the consumer, especially those with compromised immune systems. Aspergillus exposure can lead to invasive pulmonary aspergillosis, which can travel from the lungs to other parts of the body[7] and when left untreated, can be fatal.[8]

Needless to say, imprecise and rudimentary

rehumidifying efforts should not be an option for any cultivator, no matter the

scale.

Humidity Control: A Complicated Problem with a Simple Answer

Given the risks of too much moisture, many cannabis cultivators opt to run hard in the other direction and simply accept the degradation that comes with overdry product. Fortunately, it is possible to keep RH within a tight range with little monitoring or intervention, and at a low cost.

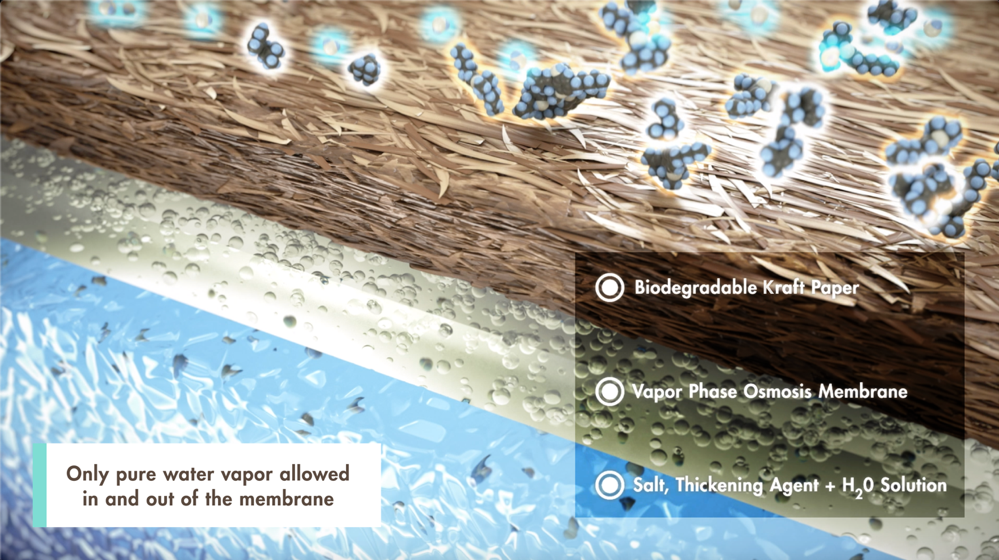

Both glycerin and salt-based humidity-control products

release water vapor as needed when the surrounding environment reaches a

certain level of aridity. However, only 2-way humidity control

technology—featuring natural saltwater formulations housed in a vapor-phase

osmosis membrane—can effectively add or reduce pure water vapor as needed to

maintain a constant, predetermined RH level in the storage container. This

results in a stable level of moisture weight in the cannabis flower. Glycerin

can be problematic because it can allow for microbial growth.[9] Salts,

however, do not have this issue and can keep moisture levels within a narrow

range. The benefits for cannabis flower are large and measurable.

Magnified illustration of 2-way humidity control

solution.

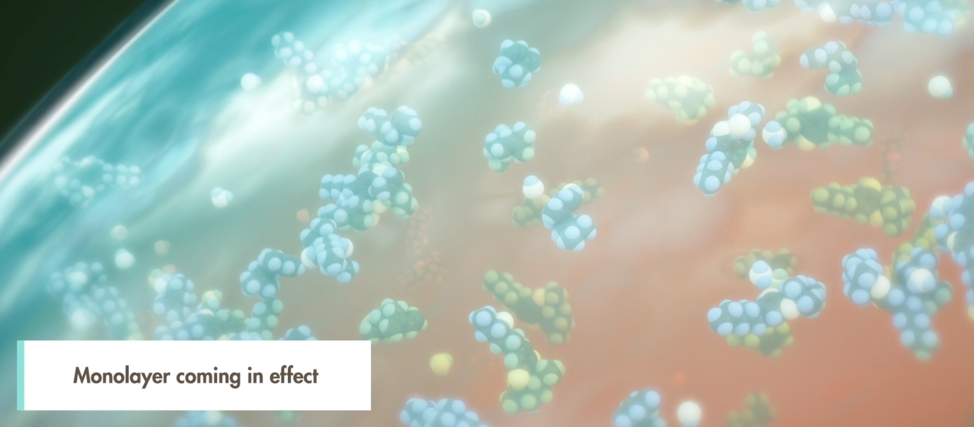

For terpene retention, 2-way humidity control coats the trichomes of cannabis flower with a monolayer of purified water—one to two molecules thick—that acts as a protective shield, keeping the terpenes from evaporating.

A third-party lab study that analyzed flower cured with 2-way humidity control solutions designed to keep RH at 62% showed that the cannabis retained 18% more terpenoids and 23% more cannabinoids than a control. As a naturally safe material, salt avoids any safety complications if the packet should become compromised (glycerin can have a laxative effect,[10] which may not be desirable for the user).

When factoring in the added profitability from increased weight, along with the value-add of enhanced quality from terpene and cannabinoid retention, the advantages of 2-way humidity control are clear.

For cultivators with tight margins, a grouping that includes most growers in this highly regulated industry, that can be the difference between operating in the red or in the black.

Concluding Thoughts: A Little Saltwater Goes a Long Way

Properly controlled humidity makes a big difference in the quality, weight, safety and profitability of cannabis cultivation and processing. Fortunately, tackling evaporative loss is easy to address with 2-way humidity control solutions designed to maintain stable optimal RH within packages or containers. Salt-based humidity control solutions with 2-way vapor-phase osmosis technology are proven to achieve substantially more desirable results than other moisture-control methods, and this could translate into substantial profit retention.

The benefits of properly storing cannabis with humidity control in mind are far-reaching for cultivators, processors and packagers. In this rapidly evolving industry, cannabis brands are building their reputations in real time, and there’s no room to fall behind.

A proven humidity control system is a needed investment for cannabis businesses of any size.

Boveda. The Original Terpene Shield™.

FASTEST WAY TO RIGHT RH FOR CANNABIS

2 POST-CURE RISKS YOU CAN CONTROL WITH PRECISE RH

WHY SALT IS REQUIRED FOR PRECISE RH IN CANNABIS STORAGE

SHOULD FLOWER HAVE A STRONG SMELL BEFORE YOU GRIND IT?

SEE HOW BOVEDA WORKS

SHOP BOVEDA

[1] https://www.astm.org/standardization-news/?q=features/two-cannabis-standards-you-should-know-about-.html

[2] https://www.leafly.com/news/science-tech/how-to-assess-thc-cbd-levels-in-cannabis-strains-products

[3] https://www.ncbi.nlm.nih.gov/pmc/articles/PMC5741114/

[4] https://www.ncbi.nlm.nih.gov/pmc/articles/PMC3165946/

[5] https://honestmarijuana.com/terpenes/

[6] https://www.bovedawholesale.com/media/Boveda_Terpene_Study.pdf

[7] https://www.ncbi.nlm.nih.gov/pmc/articles/PMC3103256/

[8] https://www.cdc.gov/fungal/diseases/aspergillosis/statistics.html

[9] http://www1.lsbu.ac.uk/water/water_activity.html#bb

[10] https://www.rxlist.com/consumer_glycerin/drugs-condition.htm