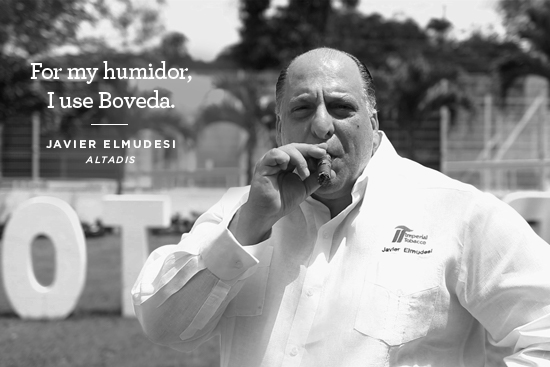

Montecristo. Romeo y Julieta. H. Upmann. Even novice cigar smokers know these biggies. Now hear from the man who runs the Altadis factory that makes these premium cigars. Javier Elmudesi manages the world’s largest handmade cigar factory—Tabacalera de Garcia in the Dominican Republic.

Watch Now: What Comes Together to Make a Premium Cigar

Cigars & Lip Service

Javier Elmudesi was born and raised in Santo Domingo, the capital of Dominican Republic

He trained as an industrial engineer. Although he started his career at Tabacalera de Garcia in 1996, his job had nothing to do with cigars. He was originally hired to manage operations for a small—now defunct—division of the factory that assembled lipstick cases for Revlon. Lipstick cases, then cigars—all lip service?

“Almost immediately, I started to pass through the cigar area,” Javier said.

Mentored By a Cigar Aficionado Hall of Famer

José Seijas mentored and coached Javier. José played a major role evolving Tabacalera de Garcia from a tobacco processor into a major cigar factory. The master blender oversaw the manufacturing of up to 55 million cigars a year for Tabacalera de Garcia before he retired in 2012. (In 2014, José founded the boutique cigar brand, Matilde with sons, Enrique and Ricardo.

“What I learned from José was the passionate way to carry the business,” Javier said.

“It is important to highlight that making cigars is not just being passionate,” he added. “It’s a combination between the passion of the buncher and roller and the quality of the leaf that makes a good cigar.”

More than 4,700 employees work at Tabacalera de Garcia, Javier said. It’s one of the largest employers in the Dominican Republic. And the cigar manufacturer is expanding every year.

Altadis creates a respectful, motivating work environment for the artisans who make its legendary cigars. “Good training, leaders treating them [employees] in the right way—with respect, with communication and recognition programs. The same time you have to combine all that with good tobacco, high quality tobacco. Then you have it all.”

Javier also heads up the Grupo de Maestros at Altadis. These world-renowned artists blend the tobacco that makes up Altadis premium cigars. Some of the masters have been working at the company for 43 years.

Guided by Javier, the team has created many highly rated cigars, including ROMEO by Romeo y Julieta, VegaFina Añejado 7 años Pigtail, Montecristo Artisan Series and Javier’s personal favorite, the Montecristo Epic.

Romeo Y Julieta Meets Boveda

“We are very proud of having brands like Montecristo. A brand like Romeo y Julieta. A brand like VegaFina. Like Don Diego,” Javier said. “We have very good brands. Brands that have been made here for a long time. Our biggest effort is to try to maintain the consistency of the quality.”

Tobacco needs the right temperature, proper humidity and appropriate time—from the farm all the way through the last stage of the cigar making process, Javier said.

Controlling a cigar’s quality, however, is difficult once those cigars leave the factory—via shipping containers, trucks, etc. Arriving at the tobacco shop, cigars could be stacked up against air conditioning and heating vents. Or displayed by windows and exterior doors. Inside of a building, heated or cooled air is always moving. So the humidity level is always changing in a tobacco shop.

Why Boveda is in Cigar Boxes

So what’s a cigar pro like Javier to do? Cigar makers use Boveda in cigar boxes to make sure the cigars stay at the proper relative humidity (RH). Maintaining the right RH, Boveda protect cigars’ flavor, condition and burn.

“My first experience with Boveda was at an IPCPR convention,” Javier said.

So Javier walked up to the Boveda trade show booth at the International Premium Cigar & Pipe Retailers Association (IPCPR) and started talking cigar humidification. Then he hustled the sales and marketing team from Altadis to the Boveda booth.

“I saw a product we could combine with our products to improve them,” Javier said. In 2015, Altadis began putting Boveda in its boxes with very good results.

Boveda is humidity control for premium cigars. At the Altadis factory, workers top the cigars, like these Montecristos, with Boveda 69% RH level before closing and sealing boxes. En route to your humidor, that Boveda will add or absorb moisture to maintain a constant 69% RH level.

No more worries for Javier about humidity control in those Altadis boxes, his booth buddies from Boveda have him covered.

Is Boveda in Your Humidor?

Cigar makers, aficionados and newbies trust Boveda to achieve and maintain a precise moisture level for premium cigars. Just slip Boveda into your humidor. With Boveda, there’s nothing else to add—no water, no gels, no beads, no nothing.