Experts Agree: Your Cannabis is Too Dry

Did you know the majority of cannabis sold in the United States is too dry? Overly dry flower is a symptom of a bigger issue facing the legal market today—terpene evaporation. As moisture evaporates, so go terpenes. With fewer terps, there is less aroma, flavor and potency.

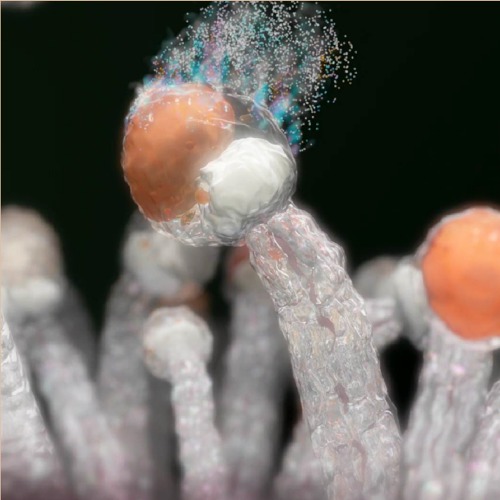

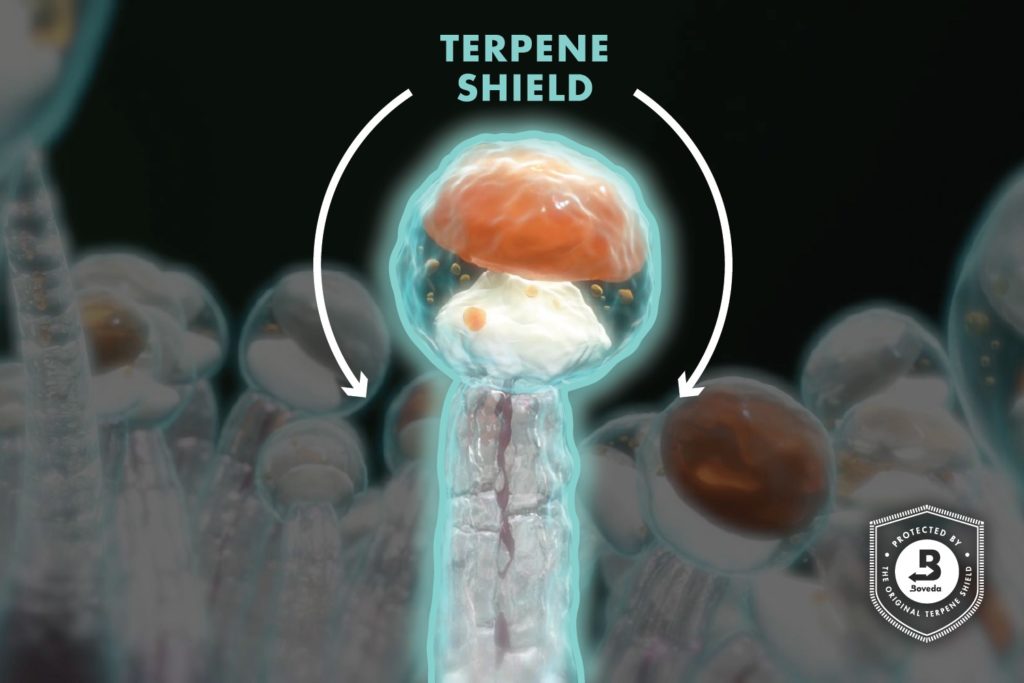

More cannabis companies are protecting their terps by creating a terpene shield around the trichome. This monolayer of water molecules preserves the good stuff in flower and prevents it from drying out too much. But do the masses know or care about terpenes? The non-profit group SaveTheTerps.org is educating the community about the risks of terpene evaporation caused by missing moisture. This is a crucial step to move the market forward.

The Cannabis Scientist spoke with SaveTheTerps.org member Andrew Samann about this mission and why terpene retention is the single most important factor producers and retailers need to consider. A respected cannabis quality expert, Samann is the Founder, principal consultant, and CEO of cannabis consultancy Orion GMP Solutions.

Excerpted from:

Why did you join SaveTheTerps.org?

Andrew Samann: As a consultant, I help companies in the cannabis industry establish efficient processes and manufacture high-quality products by applying concepts such as good manufacturing practice (GMP). If the cannabis industry wants to achieve consistent quality in cannabis products, similar to food or other commodities, it must define each product’s critical quality attributes (CQAs) – the physical, chemical, biological, or microbiological properties that must be within appropriate limits to achieve the desired product quality.

SaveTheTerps.org aims to identify cultivar-specific CQAs for cannabis flower (cannabinoid and terpene potency, moisture, visual appearance, and so on) and produce a quality score that objectively evaluates how well a given product conforms to the CQAs assigned to its cultivar.

What is the aim of the ongoing study the organization is funding?

To set acceptable limits for each attribute, we need to establish standard parameters. Inspired by a recent United States Pharmacopeia review of cannabis quality attributes and how to measure them (1), SaveTheTerps.org launched a study in partnership with a number of trusted testing labs. We procured samples of cannabis flower from dispensaries across the USA and had them tested for a variety of properties proposed by the USP review. We still have a few data sets to gather, but one result jumped out at us right away – over two-thirds of the samples we tested were below the minimum recommended water activity level. In other words, they were too dry.

Why is water activity important?

Put simply, water activity is a measure of the available (unbound) water present in a substance, measured as a proportion from 0–1 (by contrast, moisture content is the total percentage of water, regardless of whether it is bound or free). Water activity is particularly interesting because it is both a quality and a safety attribute.

The upper limit for water activity is well-established within the food manufacturing industry as 0.65. Values above this level mean there is enough water available to allow microorganisms, such as Aspergillus spp. to thrive, so manufacturers have significant and legitimate safety concerns about not drying cannabis sufficiently well. But often those valid concerns drive manufacturers to overdry the flower to such an extent that terpene retention is compromised.

Dried cannabis flower samples from California had significantly higher mean water activity (aW) than those from Colorado.

Dried cannabis flower samples from California had significantly higher mean terpene concentration (mg/g) than from Colorado.

Why should we be concerned about terpene retention?

Terpenes are abundant in cannabis plants and there is significant variation in terpene profiles across different cultivars. This genetic and chemotypic variation is a key differentiator between cannabis cultivars – it gives each cultivar the characteristic smell and taste that recreational consumers enjoy, but also has the potential to affect the product’s psychoactive and medicinal properties. Quantifying terpenes and other chemical components in a product relative to one another is critical for anyone who wants to authenticate their cultivar.

Unlike cannabinoids, terpenes are water-soluble and are easily lost through evaporation – effectively, water loss equals terpene loss. Research from SaveTheTerps.org has shown that, when water activity is at the right level, a monolayer of water forms over the trichomes, preserving the terpenes within, but if the water activity falls below 0.55, this barrier breaks down and terpene evaporation speeds up. To prevent loss of terpenes and ensure the desired effect for the end user, the relative humidity of the flower and its immediate environment (i.e., the packaging component system) should be tightly controlled. Saving the terps means preserving the flavors and the medicine.

How much attention is paid to water activity and terpene retention?

Not enough! Most stability studies done to date have focused on THC or CBD as individual active ingredients, so terpene retention is not a fully resolved variable. ASTM has published standards stating that the water activity of dried flower should be between 0.55 and 0.65, and consequently it should be kept at a humidity of 55–65 percent. But only a few states recognize water activity testing – and it is usually optional, so it’s not surprising that our study showed that most cannabis being sold in dispensaries is too dry.

With SaveTheTerps.org, we want to get the word out that water activity and terpene retention are CQAs of cannabis flower, and that regulators, growers, and consumers should consider terpene retention when preparing, storing, and buying cannabis. We can see the importance of water activity in preserving product quality by looking at another niche smokable: cigars. Cigar smokers are typically connoisseurs (humidors are commonplace!) and so manufacturers carefully control humidity and temperature throughout the supply chain to provide the quality demanded by these discerning consumers. Surely cannabis smokers – especially those who use the drug for specific medical needs – deserve similar consideration?

How can producers prevent over-drying?

When we saw the results of the water activity testing, we asked ourselves the same question – and followed it up with root cause analysis. We discovered a number of places where over-drying can occur throughout the supply chain, from distribution to processing and packaging.

For example, the initial curing processes are inherently variable; many growers hang a whole plant and allow it to dry until a branch snaps easily (not exactly a quantitative measure!). Another cultivator may cut the buds, machine-trim them, and place them on trays, where buds at the center of the tray may dry more slowly than those at the edges. Later, those buds may be bulk-packaged and sent to another facility – a few hours in an overheated truck and even more terpenes are lost. Growers and distributors need to think about every step in the supply chain and consider simple ways to prevent moisture loss.

Proper packaging is one way to reduce evaporation. Two-way humidity technology is already used in many different industries – think of the little packs you get in various consumer goods – and are an easy way to help preserve equilibrium if placed in the packaging component system at the right time.

Any other interesting results from the study you can share?

A concerning (though not unexpected) finding is that 10 percent of samples appeared to be labeled with the wrong cultivar name – the parameters for cannabinoids and terpenes were far outside the average range for the labeled cultivar. And that’s something we will be exploring further.

I think the most impactful aspect of the study is the certainty it gives; it’s great to back up our assumptions with data. We can already say with confidence that most cannabis is too dry, and that we can do better. Ultimately, SaveTheTerps.org will be sharing a lot of good information with cultivators and others on how to control quality across the entire supply chain.

You might also like:

How Never to be Named in a Mold Recall

Top 3 Reasons Why Businesses Use Boveda