Post-harvest can make or break a consumer’s experience with flower. Does the care between the grow and consumption get the credit, or attention, it deserves? Maintaining quality product throughout the supply chain is a challenge. Some licensed producers are re-evaluating whether they should do it all. Or farm out or automate some post-harvest operations.

Lean In, Listen Up and Learn:

- How automating humidity control can protect the quality of cannabis post-harvest.

- Which operations can vertically integrated producers streamline as they scale up.

- How growing cannabis differs from raising other commodities, like vegetables and tobacco.

“It’s not just throw seed in the ground and go with it, you know?”

The Cannabis Catch-Up is sponsored by Boveda, the leader in two-way humidity control for buds. Subscribe to the Boveda Cannabis YouTube Channel. Or listen to Lance Lambert’s insights live every Monday at 4:20 pm EST on The Todd Shapiro Show (SiriusXM Channel 167).

TURN UP WITH CANNABIS CONVERSATION STARTERS AT YOUR NEXT GET-TOGETHER:

- Large producers and home growers strive to stay within an ideal relative humidity for harvested cannabis. If the RH rises above 65%, cannabis is at risk for mold contamination. (1:30)

- Many people compare cultivating cannabis to growing tobacco; however, the two plants are quite different. (2:05)

- Terpenes (the essential oils that provide aroma and taste) start to evaporate when the relative humidity drops below 55%. When terpenes and moisture evaporates post-harvest, a cultivator can lose money. (2:30)

- Consuming mold-contaminated cannabis is bad for your health, especially when inhaled. (3:00)

- Mold issues are more common post-harvest than in the grow. That’s why cultivators, processors and retailers strive to stay within an ideal relative humidity range throughout harvesting, drying and curing crops. (3:15)

- The cannabis community learns about warning signs, health risks, and safety precautions concerning mold contaminations from Salmonella and E. coli outbreaks. (4:40)

- Cannabis grown and processed in dry—or humid—regions has a natural battle with humidity. (5:45)

- Devastating fires can destroy everything—from HVAC systems to pots for planting. A grow operation can lose $100k+ from a disaster, like a fire. (6:45)

- Pesticides, herbicides, companion crops and lady bugs are used to eradicate aphids in many crops; however, this is not true with cannabis. (8:55)

- By adding departments and automating systems, growers can enhance some post-harvest operations. Processes cannabis producers spin off include trimming, humidity control and branding. (10:10)

- For the best outcome, both large producers and home growers should put equal attention on drying, curing, storing, as well as growing. (11:00)

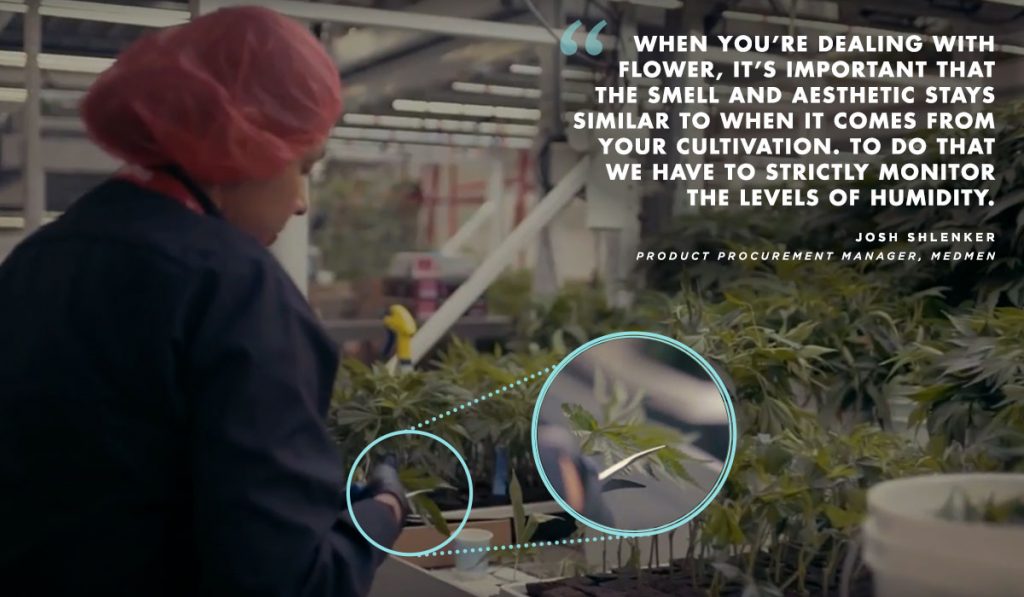

MedMen, a leading national cannabis firm based in Los Angeles, refines and standardizes operations to retain the consistency of the therapeutic and psychoactive benefits of its cannabis. Curing and storing buds within an ideal RH range, preserves the terpene content of the flower. To prevent terpene evaporation and moisture loss, MedMen integrated Boveda 2-way humidity control into operations.